Anywhere Mobility Studio Demo Processes

Overview

The STAEDEAN Anywhere Mobility Studio Framework for Microsoft Dynamics© Business Central provides an integrated and reliable framework for creating real-time Enterprise Mobile Applications. All full Microsoft Dynamics 365 Business Central functionality can easily be configured and exposed onto mobile devices. Due to the integration of the framework into Microsoft Dynamics 365 Business Central, will the familiar environment reduce the TCO.

These demo scripts explain how the pre-configured processes can be used for demo purposes based upon CRONUS International Ltd. as the standard demo company. The supported software version for the mobile process is Anywhere Mobility Studio for NAV 2015 onwards.

Common Prerequisites

The demo processes rely on the demo CRONUS data. The following is needed for most of the demo processes.

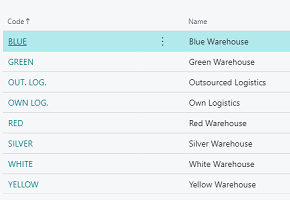

Locations

Items

- The items for the Bike Manufacturing are not available on any location;

- Furniture items are available in several locations

- The location

WHITEcontains loudspeaker items.

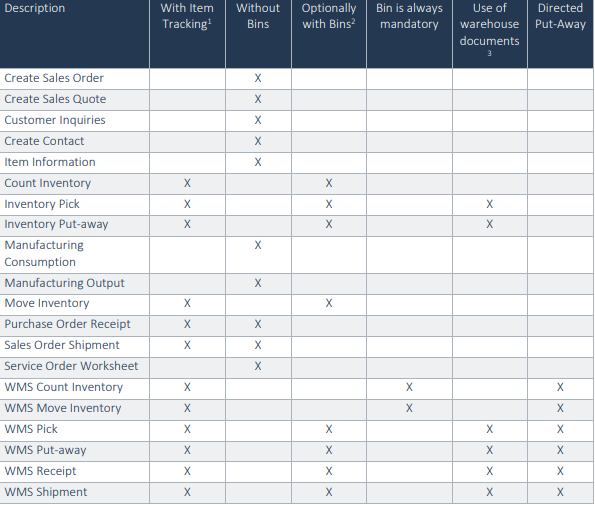

Applicability of locations

The pre-configured processes which deal with inventory transactions are based upon the use of specific location setup and in some cases the use of lots. In the next table the applicability is summarized.

Processes

Standard Processes

A series of demo standard processes can be found when drilling down the Main Menu process

The demo processes included are listed below.

- Sales Shipment

- Manufacturing Processes

- Customer Info

- Item Info

- Count Inventory

- Create Contact

- Create Sales Order

- Inventory Pick

- Inventory Put-Away 10. Move Inventory 11. Purchase Receipt 12. Sales Quote 13. Service 14. Transfer Shipment 15. Transfer Receipt

Sales Shipment

The Sales Order Shipment process supports the shipment of goods process based on a sales order, without the use of bins and warehouse shipment and pick document handling. Posting of the shipment of items at the sales orders is integrated in the mobile process.

Manufacturing Processes

The execution of a production order in Microsoft Dynamics NAV has two types of actions:

- Consumption of components (items)

- Output registration of labour/machines and finished quantities.

The Consumption Journal is used to manually post consumption to production orders. In a consumption journal, you enter the relevant information, such as the posting date, production order number, item number and quantity.

The Output Journal is used to post setup and/or run times of work- and machine centers plus the finishedquantity for each operation.The Manufacturing pre-configured processes supports the created Item Journal Lines for both the consumption and output registration including the posting of each registration.

The prerequisites for both MFG Consumption and MFG Output are the same.

Customer Info

The Customer Information process is designed as a process for lookup of customer information, like address data, open balance, outstanding orders, invoices and shipments, and internal remarks.

Item Info

The Item Information process is designed as a process for lookup of item information like description, prices, current stock,… and related information like barcodes or the bill of materials.

Count Inventory

This process supports the Inventory Counting based on two methods.

- Based upon a predefined counting list the item inventory in a location and bin is scanned and counted. The counting process stops when the counting list is completely processed at the scanner.

- Counting the inventory in a location and bin without having a counting list available. This method checks if an item is on the counting list; if not then the registration of inventory of an item is allowed by adding the item to the counting list.

For both methods, the posting of counted inventory is executed in Microsoft Dynamics BC

Create Contact

The Create Contact process supports the creation of a contact as a company and/or as a contact person. It is also possible to maintain the data of an existing contact.

Create Sales Order

The Create Sales Order process supports the creation of a sales order in Microsoft Dynamics BC on a mobile device. In this demo company CRONUS International Ltd. the Create Sales Order pre-configured process supports in all kind of locations.

Inventory Pick

The Inventory Pick process supports the pick and shipment process based on an inventory pick document, optionally with or without the use of bins. In Microsoft Dynamics BC a pick document is generated beforehand for a:

- Purchase return order

- Sales order

- Transfer order – outbound

- Production consumption

This process has a sequantial variant, please see link below

Splitting pick document lines and the posting of the pick document as receipt to the related order is integrated in the mobile process.

Inventory Put-away

The Inventory Put-away process supports the goods receipt and put-away process based on an inventory put-away document, optionally with or without the use of bins. A put-away document is generated on beforehand in Microsoft Dynamics BC for one:

- Purchase order

- Sales return order

- Transfer order – inbound

- Production output

This process has a sequential variant, please see link below

Splitting put-away document lines and the posting of the put-away document as receipt to the related order is integrated in the mobile process

Move Inventory

The Move Inventory process supports the transfer of item inventory from one warehouse to another, with or without the use of bins. Movement of inventory between bins of a warehouse is also possible. The posting of moved inventory is integrated in the mobile process

Purchase Receipt

The Purchase Order receipt process supports the order-based goods receipt, without the use of bins andwarehouse documents

Sales Quote

The Create Sales Quote process supports the creation of a sales Quote in Microsoft Dynamics BC on a mobile device.

Service

This process supports the registering of spent materials, hours and/or costs to a service order. While a service order can be a work order for one or more service items, the selection of the service item to getserviced is part of the scope of this process. Posting of the service order is executed in Microsoft Dynamics BC.

Transfer Shipment

This process supports the shipment of a transfer order from the location where there is inventory to a transit location.

Transfer Receipt

This process supports the receipt of a transfer order.

Warehouse Processes

A series of demo warehouse processes can be found when drilling down the warehouse menu item in the main menu.

The demo processes included are listed below. It is important that these processes are executed in the order displayed below.

- WMS Receipt

- WMS Put-Away

- WMS Pick

- WMS Shipment

The WMS processes share some common prerequisites, described here.

WMS Receipt

The WMS Receipt process supports the goods receipt process based on a Warehouse Receipt document, with or without the use of bins. When items should be received from a warehouse that is set up for Warehouse receipt processing, the lines should be retrieved from the released source document that triggers its receipt. A source document for a Warehouse Receipt can be:

- Purchase Order

- Sales return Order

- Transfer order – inbound

A Warehouse Receipt document is generated beforehand in Microsoft Dynamics NAV for one or more of these source documents. The posting of the Warehouse Receipt document as receipt to the related source document is integrated in the mobile process.

WMS Put-away

The WMS Put-away process supports the put-away process based on a Warehouse Put-away document, optionally with or without the use of bins. The Warehouse Put-away document contains the instructions that a warehouse employee will follow to put received items into storage. A Warehouse Put-away document is used when the location is set up to require both put-away and receipt processing. A put-away document is generated beforehand in Microsoft Dynamics Business Central based on a Warehouse Receipt. Splitting put-away document lines and the registration of the put-away document is integrated in the mobile process.

WMS Pick

The WMS Pick process supports the pick process based on a Warehouse Pick document, with or without the use of bins. The Warehouse Pick document contains the instructions that a warehouse employee will follow to pick items from the warehouse. The picking of items with lot and/or serial tracking applied is supported by the process. A Warehouse Pick document is used when the location is set up to require both shipment and pick processing. A pick document is generated beforehand in Microsoft Dynamics Business Central based on a Warehouse Shipment. The registration of the pick document is integrated in the mobile process.

This process has a sequential variant, please see link below.

WMS Shipment

The WMS Shipment process supports the pick process based on a Warehouse Shipment document, with or without the use of bins. The Warehouse Shipment document contains the instructions that a warehouse employee will follow to load items from the warehouse. The loading of items with lot and/or serial tracking applied is supported by the process.

A Warehouse Shipment document is used when the location is set up to require shipment processing. The registration of the shipment document is integrated in the mobile process

WMS Move Inventory

The WMS Put-away process supports the put-away process based on a Warehouse Put-away document, optionally with or without the use of bins. The Warehouse Put-away document contains the instructions that a warehouse employee will follow to put received items into storage.

A Warehouse Put-away document is used when the location is set up to require both put-away and receipt processing. A put-away document is generated on beforehand in Microsoft Dynamics BC based on a Warehouse Receipt.

Splitting put-away document lines and the registering of the put-away document is integrated in the mobile process.

WMS Count Inventory

This process supports the Warehouse Management System (WMS) Inventory Counting based on two methods:

Based upon a predefined counting list item inventory in a location and bin is scanned and counted. The counting process stops when the counting list is processed at the scanner completely.

Counting the inventory in a location and bin without having a counting list available. This method checks if an item is on the counting list; if not then the registration of inventory of an item is allowed by adding the item to the counting list.

Both methods supports the locations with Directed Put-away and Pick set to Yes. Registering of counted inventory for both methods is executed in Business Central.