Work Breakdown Structures

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

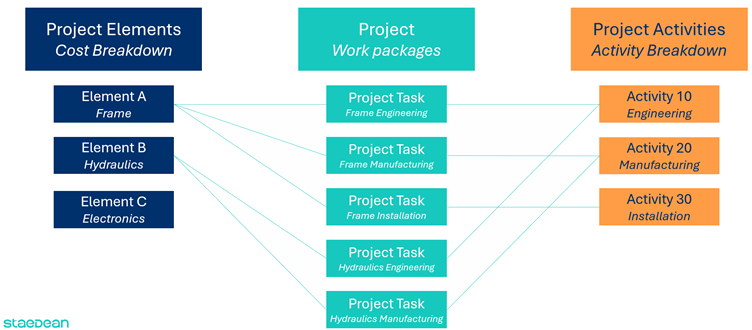

To further enhance the visibility on your project additional work breakdown structures can be created:

The Project Management Body of Knowledge (PMBOK 5) defines the work breakdown structure as a "hierarchical decomposition of the total scope of work to be carried out by the project team to accomplish the project objectives and create the required deliverables.". The basic, and mandatory, breakdown structure for Projects in Microsoft Dynamics 365 Business Central is the Project Task. Only on Project Tasks budget – and billing lines can be created, and usage posted. In IEM 2 additional work breakdown structures (WBS) have been added: Elements and Activities. Although the definition for these WBS is free the common application is to use Elements for a cost WBS and Activities for an activity based WBS. As example, based on building a machine, the total machine could be broken down in the frame, the hydraulics, and electronics. On the activity side you can distinguish between the activity of engineering, manufacturing, and installation. Again, these are just examples, the definition is free. What the above schedule also indicates is that you can combine these additional WBS to create Project Tasks as work packages:

- Project Task 1 = Engineering the Frame,

- Project Task 2 = Manufacturing the Frame,

- Project Task 3 = Installation of the Frame

- Etc.,

In this way you can allocate material and resources to specific Project Tasks and at the same time have visibility on the total cost of the element Frame as well as the total amount of Engineering spend on the Project.

Product video

See Also

- The value chain and the push/pull point

- Create project visibility

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

- JMS Road-map planning

Welcome to Industrial Equipment Manufacturing