The Industrial Equipment Manufacturing basics

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

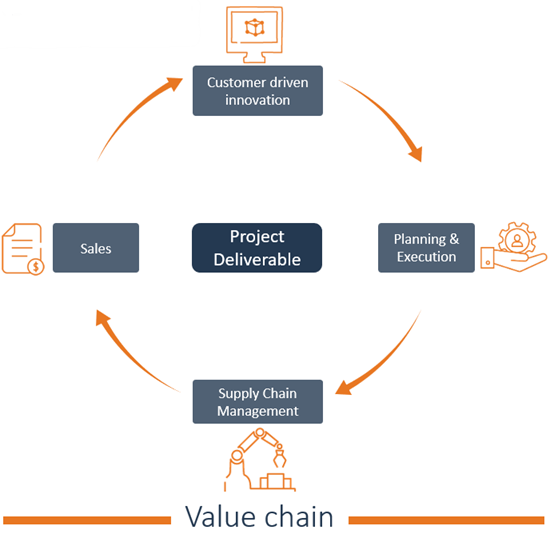

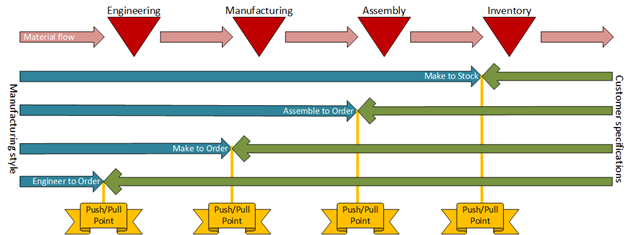

To support this style of manufacturing IEM adds functionality to each part of the value chain. The extend of being customer driven is defined by the push/pull point. The term push/pull is used in the supply chain to indicate from which direction demand is coming:

- Push initiates production in anticipation of future demand, independent from customer orders, also known as Make to Stock

- Pull initiates production from actual demand, customer order driven, also known as Make to Order

The push/pull point indicates until where in the ordering process the customer needs are considered. Each system has its pros and cons and is closely related to the type of product. A push system is usually applied for retail products being mass produced. A pull system allows for customization and usually applies to complex equipment or tools. The advantage of manufacturing based on customer specifications is in reduction in stock obsolescence, finished goods inventory, and overall waste. This advantage however comes with a cost due to the loss of economies of scale achieved in mass production. The challenge for manufacturing companies in the make to order style of manufacturing is to find the right balance between flexibility in product specifications and cost of manufacturing. That balance is represented by the push/pull point.

The most far-reaching form of customer pulled manufacturing is engineer to order. In that manufacturing scenario the push/pull point reaches all the way to the design of the product. Customer demand however is subject to fluctuation which could make the company vulnerable to under -, or over, utilization of production capacities. To achieve more stability companies will attempt to move the push/pull point back by standardizing the product in, for example, building blocks that can be manufactured in small series. In that way the company changes from engineer to order to make to order or assemble to order.

What remains important in these, to order styles of manufacturing, is the pull from the customer. In other words, the needs of the customer are considered.

On the other end of this spectrum is project-based manufacturing where the product is leading. Initially a product might have been developed based on market trends and opinion, very much like an engineer to order project. When that product has been pushed successfully into the market, actual manufacturing starts in a project-oriented environment to create maximum efficiency. In this manufacturing scenario the push/pull point is moved all the way to the completed product.

In all these scenarios it is important to have a software system that has the flexibility to move along with the push/pull point as companies, markets and products develop.

IEM supports all these scenarios from Engineer to Order to Project Based Manufacturing. IEM has been developed as an extension of Microsoft Dynamics 365 Business Central (previously known as Navision and Dynamics NAV) holding 20 years of experience in supporting this style of manufacturing.

As the experience of IEM customers shows, the product has been effective in helping companies become more competitive organizations that can turn quickly to meet changing customer needs and innovate in a collaborative manner while supporting the complete Value Chain for this style of manufacturing.

See Also

- Create project visibility

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing