Warehouse Integration

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

Industrial Equipment is often about complex machinery and tools. Especially when companies are running many of these projects at the same time it is important to have the right tools to handle the material required for these projects. As not all material is needed at the same time you must be able to store and retrieve material efficiently.

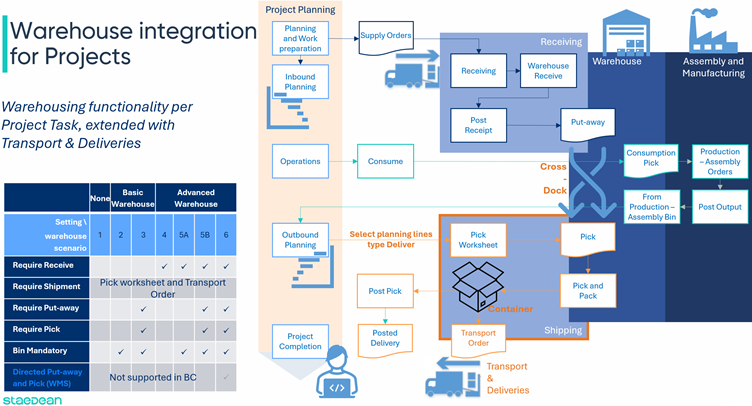

Microsoft Dynamics 365 Business Central has limitations with regards to integration of Projects into Warehousing. Material ordered for a project through a purchase order is consumed upon receipt. Also warehousing is integrated at the Project level. On the shipping side the Business Central process is complete when material is taken out of inventory (picked items are taken out of the warehouse and when posted items are taken out of inventory).

However, installation can also be part of the project. Often taking place at a, remote project site. To make installation interruptions as short as possible the required material must be shipped just in time, in the right sequence with the packages clearly indicating the contents. This means that picked and packed material can be waiting in the shipping area for some time before being moved to the Project site.

In another scenario material can be delivered by external suppliers to be shipped directly to the project site without being unpacked, stored, and picked again. In that scenario it is important to separate the cross-dock location by project or assign every project its own cross-dock location.

IEM offers integration on the Project Task level for basic and advanced warehousing scenarios including the possibility to deliver material from a Project Task, to a project site. With the added Transport and Deliveries feature goods can be packed into a container during picking and shipped with a Transport Order.

To summarize the added functionality in Project Control Suite:

- Material ordered for a project through a purchase order is received in inventory with a reservation type of order-to-order binding to the project.

- Material to be consumed in the project first needs to be picked to the To-Project Bin Code before the planning line is posted.

- When the Project Task planning line is set to application type Deliver, use the Pick Worksheet to select project planning lines type of Deliver. Based on the warehouse settings on the location card create a warehouse - or an inventory pick to collect the items.

- From the pick document open a container worksheet to create a container (box, pallet, crate, etc.) and add the picked items to this container. When the container is full set the status to closed and start a new container if required. Print a label for each container listing the content.

- Posting the pick will create a Posted Delivery for the Project Task as well as post the Project Planning Line. From the Project Task retrieve and monitor the status of the packed containers: Open, Closed, Loaded.

- Containers are added to Transport Orders. All containers with the same pick-up – and delivery address, shipping agent and – service as well as shipping date can be added to the same Transport Order. To plan multiple Transport Orders the Delivery Trip is available for all Transport Orders with the same shipping agent and – service.

- On the Project Card specify the cross-dock location for the project together with the cross-dock due date calculation date formula. For shipping set the method, agent, and service. The shipping methods are inherited on the Project Tasks together with the shipping address, when necessary this can be modified to give each Project Task its own set of shipping instructions.

See Also

- The value chain and the push/pull point

- Create project visibility

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing