Resource Integration in production (basic MES)

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

Business Central’s manufacturing module is not aware of resources while project-based companies often have a requirement to be flexible with their, human, resources. To make optimal use of their skills they might need them not only in projects but also in service – assembly or production orders.

Resource Management makes that possible through Resource Tasks which are created as a common entity between Projects, Service, Assembly and Manufacturing.

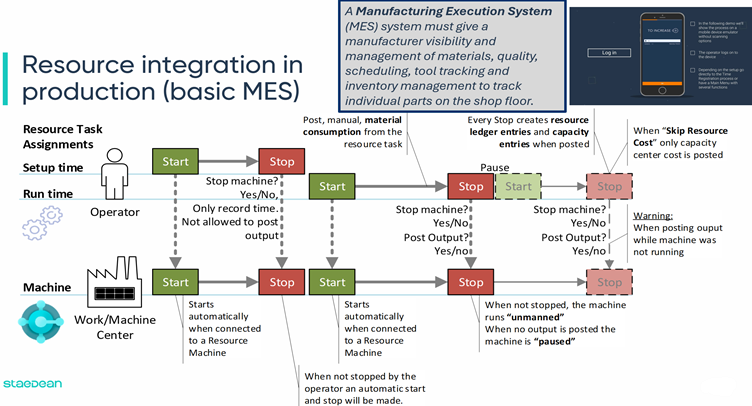

For the production department this means that resources can be added to production order operations as operators. While Business Central plans the capacity of the Work & Machine (W&M) centers the operator can start and stop the W&M center timer.

On the W&M center you can set when you want to have that center start: Not, Set-up, Run, Both.

At the start of a task the operator can select set-up or run time and based on the settings also the W&M center’s timer will start. When the operator stops an additional propmpt asks if also the W&M center’s timer must stop. If not, the W&M center is considered to run “unmanned” until the operator “signs-in” again to stop it.

Operator time is then recorded in the time sheet while the W&M center’s time is recorded immediately as a capacity entry on the production order. In that way the progress is immediately visible on the production order.

STAEDEAN also offers a BC Anywhere process that will support Resource integration in Manufacturing from a mobile device and then functions as a basic Manufacturing Execution System (MES). The flexibility of BC Anywhere allows you to add additional information to further build out this MES.

See Also

- The value chain and the push/pull point

- Create project visibility

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing