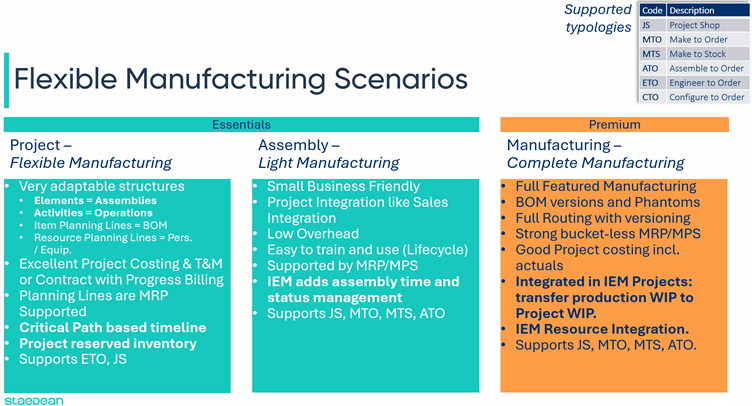

Flexible Manufacturing Scenarios

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

In the value chain for the customer driven style of manufacturing, manufacturing is the basis. As there are many variations of this style of manufacturing it is also important that the tools to support the actual manufacturing are flexible.

The flexibility being addressed here is in the organization of production. In the customer driven style of manufacture there is a large variation in manufacturing scenarios which can even vary per organization and per product. As products evolve over time also the manufacturing methods evolve with them.

Microsoft Dynamics 365 Business Central recognizes that in the licensing structure by making the manufacturing module part of the Premium license. This does not mean that you can only manufacture with the manufacturing module, on the contrary, the schedule above shows the possibilities of the Essentials license in combination with JMS. In this blog some ideas and suggestions on how to use and/or to combine these.

JOB – FLEXIBLE MANUFACTURING

The basic Project Shop works with walk-in customers that show a sketch or drawing with the question “Can you make this for me?”. Or as Wikipedia defines it:

Project shops are typically small manufacturing systems that handle project production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch projects. Project shops typically move on to different projects (possibly with different customers) when each project is completed.

As such the Project Shop - and Engineer to Order styles of manufacturing are closely related. This does not mean simple! The complexity is in working efficiently with very adaptable structures. In IEM complex structures can be decomposed with the Element and Activities work breakdowns to add more structure to the deliverable:

- An Element then becomes a sub-assembly of the deliverable with the item planning lines as components. Since these planning lines are picked up as demand by Business Central’s MRP, supply of material is taken care of being pegged to the Project through Business Central’s dynamic order tracking. When you do not want to have material supply behave “dynamic”, you can make the links between supply and demand “hard” by using Order Planning's reservation system.

- The work breakdown structure “Activities” is used to define departments (work – or machine centres) and when combined with the Elements WBS the Project Task becomes a specific operation.

When customers start to return more frequently for the same or similar products these structures can be laid down in templates so new Projects can be created efficiently.

ASSEMBLY – LIGHT MANUFACTURING

With, IEM enhanced, assembly orders a light manufacturing style of manufacturing can be implemented based on the Microsoft Dynamics 365 Business Central essentials license. Assembly orders work with the assembly BOM as linked to an item. IEM adds assembly time to the same item, so the planner has an indication of how much time is required for the assembly order. The assembly order then indicates a starting – and ending date/time based on the number of resources assigned to the assembly order.

When adding assembly items to a Project Task budget or – planning line you have the option to modify the assembly BOM and create a project specific version of that item. This function will also calculate a project cost for the modified assembly BOM. In this way you can create basic versions of your item(s) and then make them customer specific in the Project.

Assembly orders can also be used to organize subcontracted work from the Project. For example, when zinc plating is subcontracted, create an assembly BOM with the blank item and attach that to the zinc plated item. The assembly order can now be used to pick the material to be delivered to the subcontractor. Post and complete the assembly order when the zinc plated item is received.

MANUFACTURING – COMPLETE MANUFACTURING

The manufacturing module, as part of the Premium license, offers all the features, and more, as shown in the schedule at the start of this blog. IEM fully integrates this module into Projects. You can make project specific versions of the production BOM and Routing, have a project cost calculated for the project specific item and create production orders from the Project. For project specific production orders, the work in process can be transferred to the project when the production order is set to the status finished.

With IEM you are not stuck with one style of manufacturing, you can mix and match them throughout the same project. Have the standard components manufactured in small series as production orders. Assemble standard components to higher level sub-assemblies through assembly orders. Use production order routings for detailed work instructions in engineer to order. Use Project Tasks to plan final assembly or installation at the project site.

Product Video

See Also

- The value chain and the push/pull point

- Create project visibility

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing