Comprehensive Planning

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

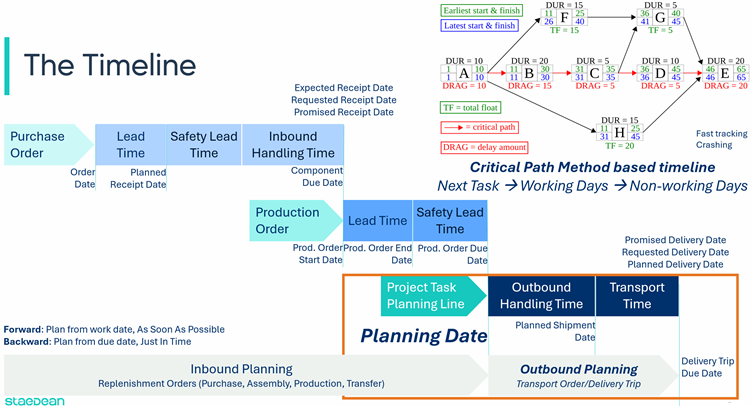

In the value chain for the customer driven style of manufacturing a detailed timeline is very important to drive the supply chain as well as the resource planning. Microsoft Dynamics 365 Business Central maintains a lot of dates to make sure inventory arrives in time.

In IEM the Planning Date on the Project Task planning line is the starting point for the material requirements planning (MRP) or Order Planning calculation. The planning date is set by the Project Task starting date to make sure material is available when the Project Task starts. From there the Business Central MRP takes over. To calculate the Project Task timeline IEM makes use of the Critical Path Method (CPM) to calculate the shortest time required to complete the project. That calculation is based on the following settings:

- Next Task which could be sequential or a set of tasks to plan Project Tasks in parallel.

- Estimated, number of working days for the Project Task

- A non-working day calendar usually to specify weekend and national holidays.

With this data CPM calculates Project Task starting and Project Task ending dates either in forward (ASAP) or in backward (JIT) direction. When one of the dates on a Project Task changes the planner can start a re-calculation of the following tasks. To support projects where material must be delivered for installation on a project site IEM adds Outbound Planning dates to the Project Task like a delivery date, set by the end date of the Project Task, as well as a planned shipment date taking the warehouse handling and shipping time into account.

See Also

- The value chain and the push/pull point

- Create project visibility

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing