Create Project Visibility

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

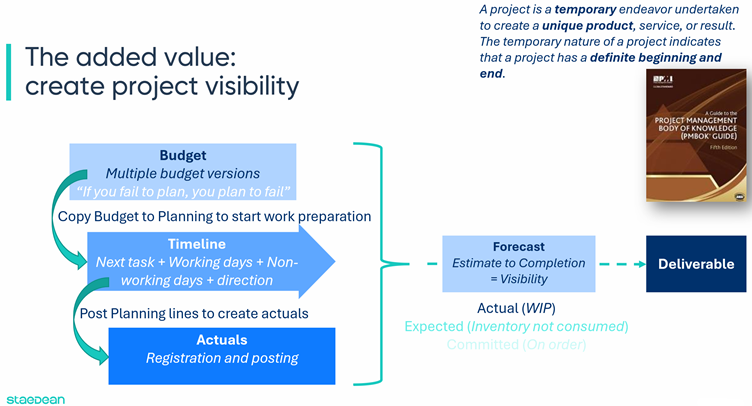

The basics for this style of manufacturing is in creating visibility on the project. As the Project Management Body of Knowledge (PMBOK Guide) defines it a project is temporary which means a beginning and an end with a pre-defined result, a deliverable.

BUDGET

A Project is temporary and creates a unique product. In other words, not a routine. For that reason, having a plan, to measure against, is essential: “If you fail to plan, you plan to fail”.

In IEM a Budget is the baseline making sure the project is calculated accurately to make the right quote, plan the correct material in the right quantities as well as the availability of your people either in resource groups or in individual resources.

TIMELINE

Projects have a definite beginning and end; within that time-frame you must realize what you have planned in the budget. Based on the customers demand, or availability of material and people, you can plan forward As Soon As Possible (ASAP) from a starting date or backwards from an ending date to deliver Just in Time (JIT).

IEM supports both planning directions by calculating the Critical Path based on estimated number of working days per Project Task, the sequence of these Project Tasks, and taking non-working days into account as specified in the Project Calendar. As budget lines are created per Project Task the budget is automatically applied to this timeline making clear when which costs can be expected.

REGISTER

Once the budget is laid out along the timeline, correct registration makes sure you maintain up to date visibility on your project and provide answers to questions like: “is the project progressing to plan?”, “what is the earned value to date?”, “how much do we estimate to complete this project?”.

IEM allows you to bind supply orders to the project and show inventory as earmarked for the Project to make costs related to the project visible as soon as possible. For the same reason Resource Tasks are automatically created from Project Tasks so, human, resources can start and stop these tasks to have their time directly recorded on the correct Project Task.

FORECAST PROGRESS

A wise man once said: “The ideal project does not exist, each time there is the opportunity to realize an approximation.” This means that the more up to date your visibility on the progress of the Project is the more opportunity you have, to take corrective actions.

IEM offers a flexible Forecasting feature that allows the project manager to compare at any time budget to actual numbers and calculate an Estimate to Completion both on values as well as quantities. The project manager can set the Progress % for each Project Task to further refine the Forecast.

See Also

- The value chain and the push/pull point

- More visibility, multiple work breakdown structures

- Project -, Project Task Status and Workflows

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing