Status control and workflows

Industrial Equipment Manufacturing (IEM) for Microsoft Dynamics 365 Business Central supports the customer-driven (pull) style of manufacturing.

Industrial Equipment often involves complex machinery or tools resulting in relatively large and complex projects. To guide project managers and project team members through this complexity IEM uses states for Projects and Project Tasks, optionally, driven by Life-cycles and supported by Workflows.

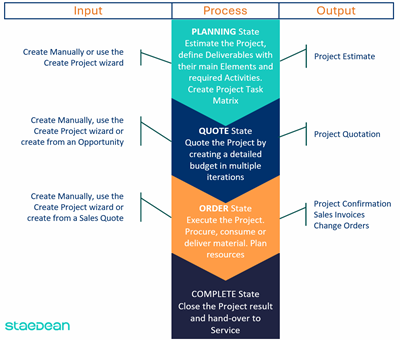

First, there is the ProjectStatus as offered by Microsoft Dynamics 365 Business Central following the stages a project goes through:

- Initiating or planning

- Quoting

- Executing, Monitoring and Controlling

- Completing and closing

Project Control Suite, in combination with Item Status Management, can be extended with Project Status Management to manage the project's business process through a lifecycle.

In Marketing and Sales integration we’ll explain more about the sales processes leading to a Project.

IEM status management for Projects is intended to work bottom-up:

- When all planning lines are completed the Project Task can be completed. When the remaining quantity on a planning line is 0, the line status is set to Completed. This status can also be set manually with the Change Status action or when a Resource marks the task as Complete.

- When all Project Tasks are completed the Project can be completed. A batch report is planned to cycle through all planning lines for a Project Task, when all planning lines have status Completed the Project Task is set to Completed.

Document Approval workflows can be created to further support these processes. An example has been added to Project Control Suite for approving a Project Change Order. This approval workflow can be installed from a workflow template.

A Project Lifecycle is available as a separate app based on the Lifecycle Base app.

See Also

- The value chain and the push/pull point

- Create project visibility

- More visibility, multiple work breakdown structures

- Marketing and sales integration

- Comprehensive planning

- Flexible manufacturing scenarios

- Warehouse integration for Projects

- Resource integration in manufacturing (basic MES)

- Service integration (Servitization)

Welcome to Industrial Equipment Manufacturing