Manufacturing Integration - Resource as Operators

Microsoft Dynamics Business Central does not use Resources in manufacturing; instead, human, capacity is defined in Work Centers and / or Machine Centers. In order to realize an integrated Resource Planning Industrial Equipment Manufacturing (JMS) Manufacturing Integration links Resources to Machine Centers which means also Resource Tasks and Assignments can be created.

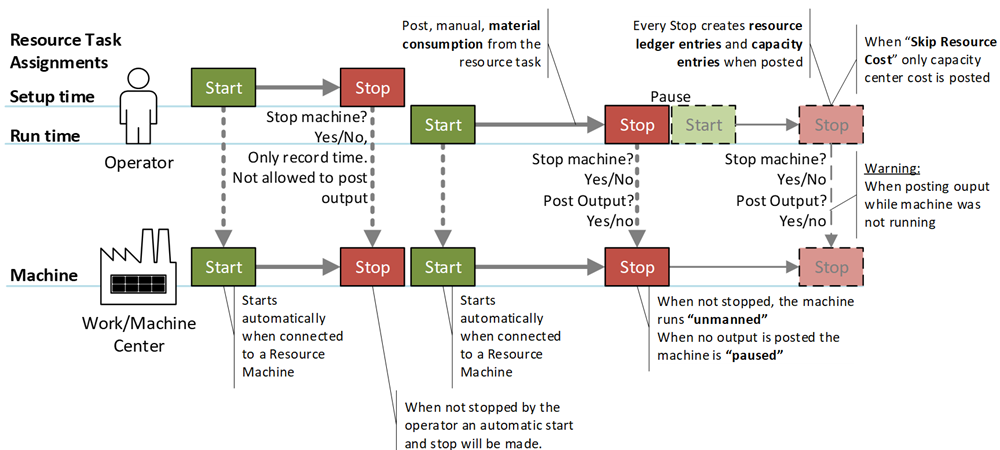

This feature makes it possible to separate operator time from machine time with the following advantages:

- Makes detailed planning and calculation possible.

- Enables "unmanned" machine hours where the machine is started, paused and stopped by the operator.

- With the added resource task feature to also post material consumption it creates the basis for shop floor management on mobile devices supported by BC Anywhere.

The functionality consists of the following elements:

| See | Learn |

|---|---|

| Learn how to assign Resources to a Capacity Center. | Resource Allocation |

| Learn how to set up the costing when Resources are combined with Capacity Centers | Resource Cost Allocation |

| Learn how to combine tasks from different production orders | Combine Operations |

See also

Return to Resources in Manufacturing

Feedback

Submit feedback for