Manufacturing Integration - Combine operations

Combined task restrictions

Combining production order operations is useful when the same item is manufactured in several production orders. In that case you can combine one of the operations into one, resource, task. The following restrictions apply to combining production operations:

- Combined Resource Tasks can only be created from a Planned - or Firm Planned production order and for the same item.

- Once the production orders are Released combined operations can be deleted from or added to the Combined Resource Task provided that no postings have been made yet.

- Operations can only be combined per Production Order Status, it is not allowed to combine an operation from a Planned order with an operation from a Firm Planned order or vv.

- Only 1 operation per production order can be combined, in other words a production order cannot be included in more than one combined resource task.

- It is only allowed to post to a combined resource task when all production orders included in that task have been released.

Creating combined tasks

Preferably Combined Resource tasks are handled from the Operations Planning page as shown in the Team lead role center ribbon.

- From the Team Lead role centre open the Operations Planning.

- From this list of operations, highlight the Operations to be completed (hold down the Ctrl key to select multiple lines) based on the restrictions as mentioned above.

- The planner can sort on each of the columns for an easier overview.

- When selected use the Combine Operations action in the ribbon to create the Combined Task, confirm the prompt to complete this action.

- Use the Required Material action in the ribbon to show the required material for the Combined Task as per the Routing Link Code. The material quantities can be updated from this page as expected consumption.

- Use the Change Production Order Status action to change the status of the Planned - or Firm Planned production order to Released.

- When changing the status from the Production Planning page all production orders combined in the task will change status.

- When for a Planned or Firm Planned Production Order the status is changed from the resp. production order list the status is changed individually. However, it will not be possible to post to the combined task before all combined production orders are released.

- When one of the production orders with a combined task is selected the Show Combined Lines action will open a list with all the operations in that combination. From this page the combined task can be modified: You can delete lines only when no postings have been made. Only operations with the same criteria can be added:

- Production Order Status,

- Capacity Center Type and No.,

- Routing Link Code.

Combined task material allocation and consumption

From the Combined Task Lines page, the Material Consumption can be opened from where the actual consumption can be specified and posted:

Material Consumption will open the list of components that are linked to the combined operations through the Routing Link Code.

- With the Item Filter one of the components can be selected.

- In the Actual Consumption Quantity, the total component consumption, can be specified.

- The Actual Consumption Quantity is distributed over the lines weighted with the original quantity.

- With Post the selected item, with adjusted quantity, will be posted.

Combined task capacity posting

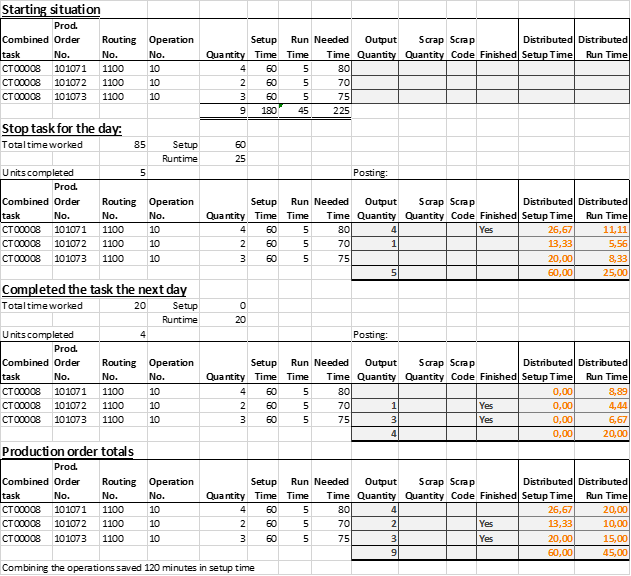

In the same way as in resource tasks, capacity is posted based on the duration (= stop time -/- start time) in the time input line. However, in a combined task the time must be distributed to the production orders combined in the task.

Important part of the output posting are the output quantities, how many units have been completed and is the operation finished or not?

The posting algorithm assumes the following:

- Output and scrap quantities as well as scrap codes must be specified per production order at posting time.

- Time is distributed over the operations automatically with the production order quantity as a weight factor.

- Setup and run times are tracked separately based on the assignments to the resource task and the setting on the work/machine center.

- Preferably the machine is stopped when setup is completed to properly record the setup time.

- When the operator does not stop the machine when setup is completed, the program stops the time input and restarts a new time input line. Assumed is that a runtime assignment will start immediately following the setup assignment.

The below posting example shows the effects of combined tasks on setup time:

See Also

Return to Resources Integration