IEM - Advanced Job Management

Design Detail: Critical Path Method

As of the 2017 release of Industrial Equipment Manufacturing for Microsoft Dynamics NAV, the Critical Path Method or CPM has been incorporated in the Advanced Job Management functionality area. That means you will be able to use the CPM approach in your project planning.

Understanding what CPM does

CPM is a project modelling technique originally developed in the 1950s. In various iterations, it has been used in manufacturing, engineering, plant maintenance, and many other disciplines. Many project-based manufacturers rely on a modern flavour of CPM. Today, we would describe CPM as an algorithm that could apply to any project which involves multiple, interdependent activities:

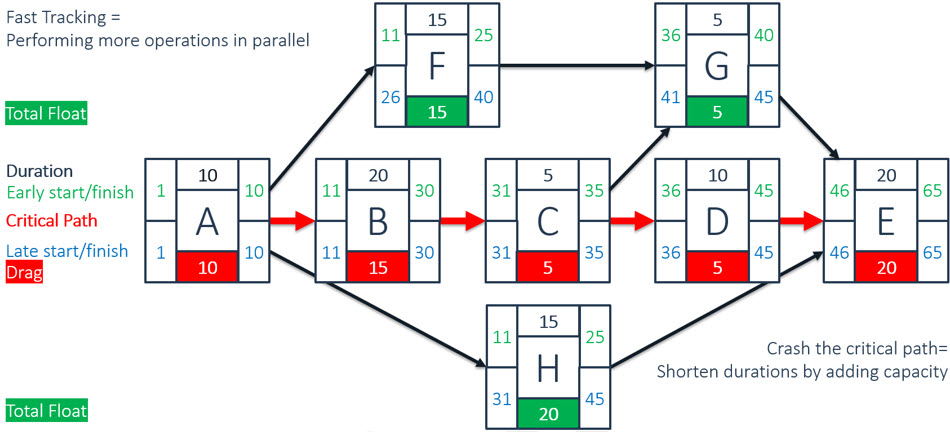

In CPM, you calculate the shortest time possible to complete a project. The calculation method establishes the longest path of activities in reaching your project goal, along with the earliest and latest times that each activity can start or finish without lengthening the project. CPM determines which activities are critical - they are on the longest path - and which, parallel activities, can be delayed without extending the project, a property known as "float".

Visual, intuitive, and efficient CPM

In the Advanced Job Management module of Industrial Equipment Manufacturing, you will find CPM enabled by means of a number of changes and enhancements. Take a look at the screen image below to get a sense of how this works. CPM-related updates include the following:

- Every Job Task can point to one or more Next Tasks. There is no separate setting for serial or parallel data calculations and previous tasks.

- When you Initialize Task Dates, you can either calculate Job Task dates forward from the Job starting date or backward from its ending date. Once the first task is underway, you can only perform forward calculations. The solution calculates the critical path and shows Job Task dates in red.

- In a separate column, Parallel Tasks indicate float days in green. You can move them with the number of floating days without disturbing the critical path.

Note: On the Job Card, Planning Tab, you can set the Starting Point to Earliest, the parallel task will start on the earliest starting date or Latest to let the task start at the latest starting date.

- A Planning Overlap alerts you to recalculate the critical path when the number of days or the end date has changed in such a way that there is an overlap with the next Job Task.

- When you change Job Task Dates planning conflicts may occur on the Job Task Planning lines. The Job Planning Line will be highlighted (ambiguous, check Colouring the planning lines. In the Job Task Information fact box the Item Planning Lines will change to red. when one of the Job Planning Lines has this warning state.

- The fields indicating duration and start and end dates are now linked: when changing a duration a new end-date will be calculated, when changing a date a new duration will be calculated.

- The Calculate Task Planning action will only be visible when there is a planning overlap. The Calculate Task Planning action only performs a Forward calculation and in this example change the ending date of the Job. Initialize Task Planning will calculate in both directions, based on the settings in the Job Card however re-calculate all Job Tasks

Milestones

A Milestone is a Scheduled event that indicates the completion of a major deliverable event (or a set thereof) of a project. Milestones are measurable and observable and serve as progress markers (flags) but, by definition, are independent of time (have zero durations) therefore no work or consumption of resources is associated with the milestone.

In IEM the Milestone sets a marker in the Job's time line which is not re-calculated by the Calculate Job Task action. It's objective is to set a relation to the original time line. Job Tasks of the type "Milestone" will not accept Budget or Planning lines neither is it possible to set a Next Task to or from the Milestone.