Pick for Production or Assembly in Basic Warehouse Configurations

How you put away your pick components for production or assembly orders depends on how your warehouse is set up as a location. For more information, see Setting Up Warehouse Management.

Pick for Production in Basic Warehouse Configurations

Flushishing method also affects the flow of components in production. For more information, see Flush Components According to Operation Output.

In advanced warehouse configurations where locations require both picks and shipments, you must use the Warehouse Pick page to bring components with flushing method set to Manual, Pick + Forward, Pick + Backward to production orders. For more information, see Pick for Production or Assembly in Advanced Warehouse Configurations.

In basic warehouse configurations where the location requires pick processing but not shipment processing, you can also use the Inventory Pick page to organize and record the picking of components with flushing method set to Manual. When you register an inventory pick for an internal operation, such as production, the consumption of the picked components is posted at the same time. Alternatively you can use Inventory Movement with reference to a source document to bring components with flushing method set to Manual, Pick + Forward, Pick + Backward to production orders.

When production operations are integrated with warehouse processes, either by bins or by directed put-aways and picks, the bin from which the components are consumed is the bin that is defined on each production order component line. All required components must be available in that bin. Otherwise, the manual or flushed consumption posting is stopped for that component.

Inventory Movement with references to the source document and Warehouse pick cannot be used to pick components with flushing methods Forward and Backward. Inventory Pick cannot be used to pick components with any flushing method but Manual. To handle remaining components, use Inventory Movement without reference to a source document. For more information, see Move Components to an Operation Area in Basic Warehouse Configurations.

[!NOTE]

The following important differences exist between inventory picks, inventory movements, and warehouse picks:

- When you register an inventory pick for an internal operation, such as production, the consumption of the picked components is posted at the same time. When you register an inventory movement or warehouse pick for an internal operation, you only record the physical movement of the required components to a bin in the operation area without posting the consumption.

- When you use inventory picks, the Bin Code field on a production order component line defines the take bin from where components are decreased when posting consumption. When you use inventory movements or warehouse pick, the Bin Code field on production order component lines defines the place bin in the operation area where the warehouse worker must place the components.

A system precondition for picking, or moving, components for source documents is that an outbound warehouse request exists to notify the warehouse area of the component need. The outbound warehouse request is created whenever the production order status is changed to Released or when a released production order is created.

To pick production components in basic warehouse configurations using Inventory Pick

In basic warehouse configurations where the location is set up to use picking only, you can pick components for production activities with the Inventory Pick page. For more information, see Pick Items with Inventory Picks.

- Choose the

icon, enter Inventory Picks, and then choose the related link.

icon, enter Inventory Picks, and then choose the related link. - To access the production order components, choose the Get Source Documents action, and then select the released production order.

- Perform the pick, and then record the actual picking information in the Qty. to Handle field.

- When the lines are ready for posting, choose the Post action. The posting creates the necessary warehouse entries and posts the consumption of the items.

You can also create an Inventory Pick directly from the released production order. Choose the Create Inventory Put-away/Pick/Movement action, select the Create Invt. Pick check box, and then choose the OK button.

Alternatively, you can use the Inventory Movement with reference to the source document to move items between bins. You will need to register consumption separately. For more information, see Batch Post Production Consumption

Pick for Assembly in Basic Warehouse Configurations

In advanced warehouse configurations where locations require both picks and shipments, you must use the Warehouse Pick page to bring components to assembly orders. For more information, see Pick for Production or Assembly in Advanced Warehouse Configurations.

In basic warehouse configurations, you can also pick for assembly orders with the Inventory Movement page.

In basic warehouse configurations where the location requires pick processing but not shipment processing, the Inventory Pick page is also used to pick, assemble, and ship for sales order where items must be assembled before they can be shipped. For more information, see Handling Assemble-to-Order Item with Inventory Picks.

Handling Assemble-to-Order Items with Inventory Picks

The Inventory Pick page is also used to pick and ship for sales where items must be assembled before they can be shipped. For more information, see Sell Items Assembled to Order.

Items to be shipped are not physically present in a bin until they are assembled and posted as output to a bin in the assembly area. This means that picking assemble-to-order items for shipment follows a special flow. From a bin, warehouse workers take the assembly items to the shipping dock and then post the inventory pick. The posted inventory pick then posts the assembly output, the component consumption, and the sales shipment.

You can set up Business Central to automatically create an inventory movement when the inventory pick for the assembly item is created. To enable this, you must select the Create Movements Automatically field on the Assembly Setup page. For more information, see Move Components to an Operation Area in Basic Warehousing.

Inventory pick lines for sales items are created in different ways depending on whether none, some, or all of the sales line quantities are assembled to order.

In regular sales where you use inventory picks to post shipment of inventory quantities, one inventory pick line, or several if the item is placed in different bins, is created for each sales order line. This pick line is based on the quantity in the Qty. to Ship field.

In assemble-to-order sales where the full quantity on the sales order line is assembled to order, one inventory pick line is created for that quantity. This means that the value in the Quantity to Assemble field is the same as the value in the Qty. to Ship field. The Assemble to Order field is selected on the line.

If an assembly output flow is set up for the location, then the value in the Asm.-to-Order Shpt. Bin Code field or the value in the From-Assembly Bin Code field, in that order, is inserted in the Bin Code field on the inventory pick line.

If no bin code is specified on the sales order line, and no assembly output flow is set up for the location, then the Bin Code field on the inventory pick line is empty. The warehouse worker must open the Bin Contents page and select the bin where the assembly items are assembled.

In combination scenarios, where a part of the quantity must first be assembled and another must be picked from inventory, a minimum of two inventory pick lines are created. One pick line is for the assemble-to-order quantity. The other pick line depends on which bins can fulfill the remaining quantity from inventory. Bin codes on the two lines are filled in different ways as described for the two different sales types respectively. For more information, see the “Combination Scenarios” section in Understanding Assemble to Order and Assemble to Stock.

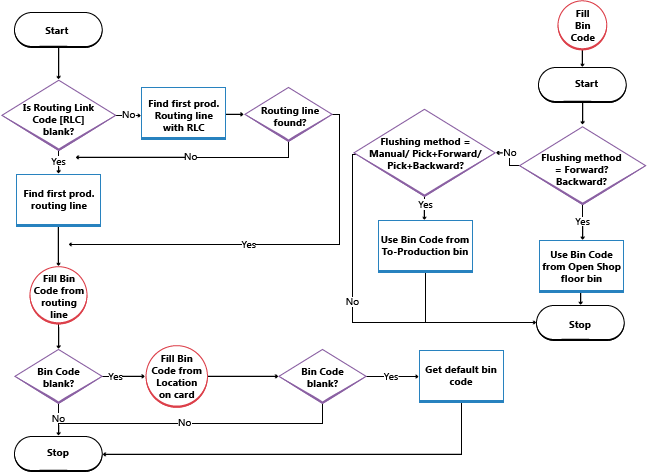

Filling the Consumption Bin

This flow chart shows how the Bin Code field on production order component lines is filled according to your location setup.

See Also

Warehouse Management

Inventory

Setting Up Warehouse Management

Assembly Management

Design Details: Warehouse Management

Work with Business Central

--- author: edupont04